|

|

|

/ Home / About US / Products / Facilities / Supports / |

Home>Products>Conveyor Belts>PVC&PVG Conveyor Belt

|

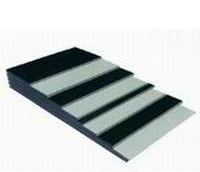

PVC Conveyor Belt

|

| Structure: |

|

PVC stands for the solid woven belt with PVC cover.

Both top and bottom cover are PVC,the belt can be used to carry dry materials at the slope no more than 16°.

|

| Feature: |

|

Good fire resistant and antistatic properties,light weight,high strenghth,supper anti-ripping and impact resistance. |

| Usage: |

|

Widely used in coal mining and other working conditions that need fire resistant and antistatic properties. |

Technical Data of PVC belt:

| Type |

680s |

800s |

1000s |

1250s |

1400s |

| Elongation strength(N/mm) |

Longitudinal |

680 |

800 |

1000 |

1250 |

1400 |

| Lateral |

265 |

280 |

300 |

350 |

350 |

| Elongation Rate(≥%) |

Longitudinal |

15 |

| Lateral |

18 |

| Anti-ripping strength(N≥) |

1090 |

1180 |

1180 |

1540 |

1540 |

| Min.thickness of the belt(mm) |

9.1 |

9.6 |

9.6 |

10.1 |

10.1 |

| Min.thickness of the solid woven Ply(mm) |

7.5 |

8 |

8 |

8.5 |

9 |

| Weight(kg/m2) |

12 |

12.7 |

12.7 |

13.3 |

13.3 |

|

PVG Conveyor Belt

|

| Structure: |

|

PVG stands for the solid woven belt with PVG cover(nitrile rubber).

Both top and bottom cover are PVG,the belt can be used to carry materials mixing some water at the slope no more than 20°.

|

| Feature: |

|

Good fire resistant and antistatic properties,light weight,high strenghth,supper anti-ripping and impact resistance. |

| Usage: |

|

Widely used in coal mining and other working conditions that need fire resistant and antistatic properties. |

| Type |

680s |

800s |

1000s |

1250s |

1400s |

| Elongation strength(N/mm) |

Longitudinal |

680 |

800 |

1000 |

1250 |

1400 |

| Lateral |

265 |

280 |

300 |

350 |

350 |

| Elongation Rate(≥%) |

Longitudinal |

15 |

| Lateral |

18 |

| Anti-ripping strength(N≥) |

1090 |

1180 |

1180 |

1540 |

1540 |

| Min.thicknees of the belt(mm) |

9.1 |

9.6 |

9.6 |

10.1 |

10.1 |

| Min.thickness of the solid woven Ply(mm) |

7.5 |

8 |

8 |

8.5 |

9 |

| Thickness of the cover(mm) |

Top cover |

1.0 |

2.5 |

3.0 |

4.5 |

6.0 |

| Bottom cover |

1.0-1,5 |

| The technical data of cover |

Hardness of rubber cover(shore hardness durometer,type A) |

58-65 |

| Hardness of plastic cover(shore hardness durometer,type A) |

75-80 |

| Tensile strength(MPa≥) |

10 |

| Elongation rate(%≥) |

350 |

| Wear & Teear(cm³/1.6km≤) |

0.8 |

Connection strength between rubber

Cover & sold woven core(N/mm≥)

When thickness of rubber cover≤1.6mm |

3.15 |

Connection strength between rubber

Cover & sold woven core(N/mm≥)

When thickness of rubber cover≤1.6mm |

4.0 |

|

|