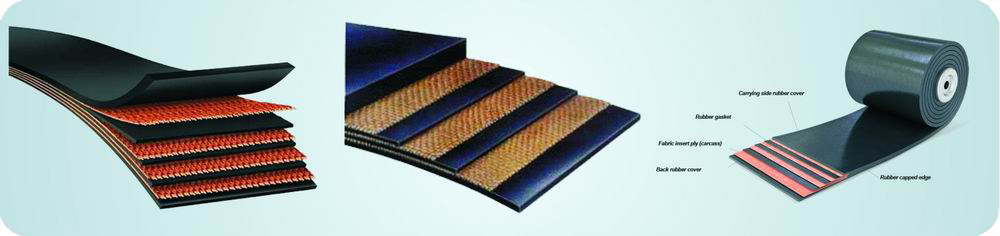

MULTI-PLY FABRIC CONVEYOR BELTS

Nylon conveyor belt,

Nylon is one of the best quality synthetic fibers that the rubber industry uses nowadays. The nylon canvas is woven by nylon fibers both in warp and in weft, it is the most widely used fabric in rubber industry, and its outstanding merits are its high abrasion resistance, high tensile strength and good fatigue resistance. Conveyor belts with nylon canvas inside have the characteristics of thin belt body, high tensile strength, and good shock resistance, and good trough ability, high adhesion between plies, splendid flexibility and long working life.

NN-100, NN-150, NN-200, NN-250, NN-300, NN-400, NN-500

Cotton conveyor belt has relatively small deformation under high temperature conditions, suitable for short-distance and light-load transportation of materials. Polyester cotton conveyor belt is the upgraded product of the cotton conveyor belt, and its tension resistant body is woven by polyester cotton fibers in warp and cotton fibers in weft. Its comprehensive physical and mechanical characteristics are obviously better than those of cotton conveyor belt, especially the belt body is thinner and lighter, the belt has better shock resistance and thus the belt has better performance and can reduce energy and material consumption for users.

CC56, TC70

Polyester conveyor belts, also called EP conveyor belts, whose tension resistant body is canvas woven by polyester in warp and polyamine in weft. The belts have the characteristics of low elongation in warp and good trough ability in weft, good water resistance, and good wet strength, no mould, suitable for medium, long-distance and heavy-load transportation of materials.

EP-80, EP-100, EP-150, EP-200, EP-250, EP-300, EP-350, EP-400, EP-500

Multi-ply fabric belt specification:Belt Type | Fabric Type | Single Fabric Strength (N/mm) | Single Fabric Thickness (mm) | Cover Thickness(mm) | Ply | Width Range (mm) | Length(m)/Roll | Top Rubber | Bottom Rubber | CC Belt | CC--56 | 56 | 1.10 | 3-16 | 0-10 | 3-12 | 300-7400 | 20-1000 | NN Belt | NN100 | 100 | 0.70 | 3-16 | 0-10 | 2-10 | 300-7400 | 20-1000 | NN150 | 150 | 0.75 | NN200 | 200 | 0.90 | NN250 | 250 | 1.15 | NN300 | 300 | 1.25 | NN400 | 400 | 1.50 | EP Belt | EP100 | 100 | 0.75 | 3-16 | 0-10 | 2-8 | 300-7400 | 20-1000 | EP150 | 150 | 0.85 | EP200 | 200 | 1.00 | EP250 | 250 | 1.20 | EP300 | 300 | 1.35 | EP350 | 350 | 1.50 | EP400 | 400 | 1.65 |

EP630/4-1200-6+2 AS M

EP: Basic strength material is EP fabric

630/4: Tensile strength in warp is 630N/mm,with 4 plies EP fabric

1200: belt width is 1200mm

6+2: Thickness of top and bottom cover rubber 6mm,2mm

AS M: Cover rubber grade(According to AS-M)

Based on rubber cover, conveyor belts can be categoried as following,

| Type |

Corresponding Standards | | Ultra-high abrasion resistant | Shore abrasion≤70mm3 | | High abrasion resistant | AS1332 A,DIN22102 W | | Impact and abrasion resistant | DIN22102 X Y, AS1332 M N, JIS K6322 A S,GB/T7984 H D | | Heat resistant | ISO 4195,HG/T2297,GB/T20021 | | Flame resistant & Anti static general use | DIN 22102 K | | Flame resistant & Anti static for coal mine use | DIN22109 V | | Oil resistant | HG/T3714 | | Acid/alkali resistant | HG/T3782 | | Cold resistant | HG/T3647 | | Ozone resistant | RMA (ASTM D1171) |

|